Saving energy at the drawing board

Pentas Moulding from Almelo uses the cashback promotion by Overijssel Province for high-speed doors. But that is just a minor measure considering what the plastics specialist is undertaking to save and generate energy. ‘We created a plan to ensure our continuous commitment to saving energy’, says owner Marthijn Koorn. ‘We contribute to the energy transition in other ways as well, by delivering products for windmills, for example.’

From toys to agricultural machines

The family-run business was founded in 1975 as a designer or windsurfing boards and went on to become the ultimate specialist in custom plastic product manufacturing with rotational moulding. From toys to plastic parts for agricultural machines, flower pots, lamps and urinals. You will find Pentas Moulding’s products anywhere.

Pentas Moulding’s efforts

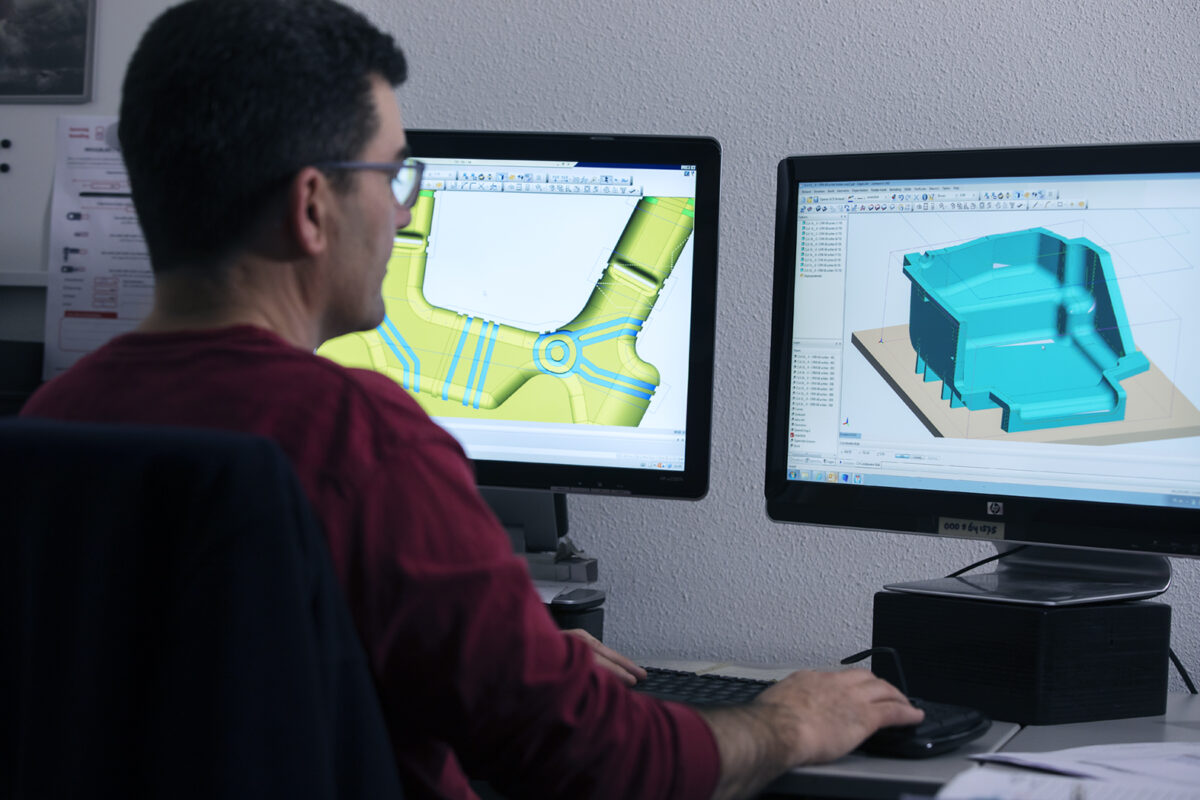

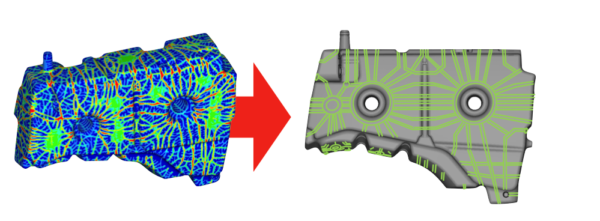

The process of melting plastics consumes a lot of energy. Pentas Moulding aims to make the process more energy efficient from the drawing board onwards. The designs are made as lightweight as possible. The company developed a ribbed structure a few years ago and was even able to patent it. Marthijn: ‘Lightweight construction reduces the energy consumption and benefits the environment in other ways as well. Such as by reducing the amount of raw materials and transportation.’ The company is also improving the insulation of their machines, mostly ovens, and has converted all lamps to LED lighting some time ago. In addition, they try to limit outage to a minimum. The roof holds 1,670 solar panels and high-speed doors have been installed.

Main driver

Pentas Moulding views its commitment to sustainability as a self-evident part of its operation. ‘As a company, we feel a responsibility to contribute to a healthy environment. For society, our staff and our clients. Because they, too, are finding it increasingly important to do business with suppliers who are committed to sustainability. Plus, it is simply part of good employer practice to tend to the world we work and live in.’

What other plans are in the pipeline?

‘We meet with our energy consultants on a regular basis to see what we can do. We want to install more solar panels. We will be checking our compressor system to ensure no energy is lost due to leaks. And we will be upping the ante on our machine monitoring to improve efficiency. Plenty of plans!’