Collaboration

Lighter tank saves fuelThanks to our sophisticated wall thickness design, the new fuel tanks are 25% lighter with identical stability. This allows CLAAS to improve their fuel efficiency without compromising on safety.

We manufacture custom plastic products, exactly the way you envision it. And more lightweight, stronger and more sustainable if possible. Because we perfect the technique of mould construction and rotational moulding every day.

About Pentas

The possibilities of plastic rotational moulding are endless. From fuel tanks for agricultural machines and slosh dampers for windmills to toilet cabins… The more challenging the better. It takes a lot of technical knowledge and boldness to realise the right future-proof solutions. And we have everything it takes to do just that.

Rotomoulding

Collaboration

Lighter tank saves fuelThanks to our sophisticated wall thickness design, the new fuel tanks are 25% lighter with identical stability. This allows CLAAS to improve their fuel efficiency without compromising on safety.

Working method

Clients appreciate in-house mould constructionIn a nutshell, agility and confidential information security are the benefits of in-house mould construction.

Pentas

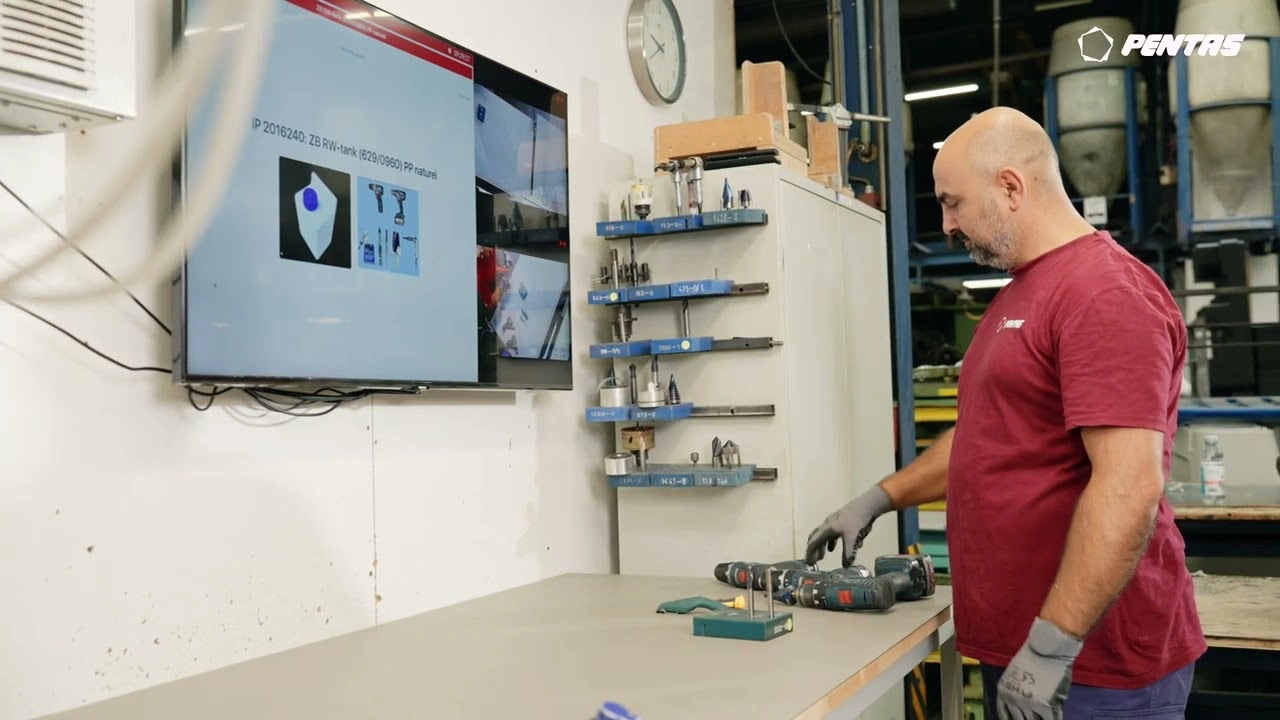

Pentas presents practical AI applications at Tech DialoguesOn December 13, 2024, we welcomed deputy Erwin Hoogland from the province of Overijssel. Pentas is the first company in Overijssel to receive a grant under the INDUSTR_I4.0 program, marking a significant milestone. In this blog, you’ll discover more about the program and how Pentas is leveraging AI technology to transform production processes.

Pentas

Pentas presents at ARM-CEOn Monday 24 and Tuesday 25 November, the annual congress of the Association of Rotational Moulding Central Europe (ARM-CE) took place. This year, Marthijn and Sadegh traveled on behalf of Pentas to Belgium, where the event was held in Hasselt. During this two-day congress, various companies and knowledge partners gave presentations on developments within the rotomoulding industry. Sadegh and Marthijn also presented the progress Pentas is currently making in robotising post-processing.

Markets

Rotationally moulded toysToys for schools, amusement parks, playgrounds and home use are increasingly being produced through rotational moulding. And that’s no coincidence: rotational moulding offers unique advantages for designers and consumers. Rotationally moulded toys are strong, durable, safe, and offer unparalleled design freedom. In addition, new designs can be brought to market quickly and cost-effectively. In this article, you'll discover why more and more toy designers are choosing rotational moulding.

Rotational Moulding

Rotational moulding vs. vacuum formingDo you want to have a plastic product manufactured and are you hesitating between rotational moulding and vacuum forming? Both production techniques have their own advantages, depending on the design, batch size and desired properties. Pentas specialises in rotational moulding, but we understand that not every product is suitable for this. Vacuum forming is an alternative production method with different characteristics and advantages. In this article, we compare both techniques so you can better determine which method is most suitable for your product.