Robots for Efficiency and Consistency in the Production Process

At Pentas, automating processes has been ingrained in our DNA since our inception. We embrace this strength by deploying a series of specialized robots that support our production process and our colleagues. From accurately weighing and dosing raw materials to advanced robotic operations in the post-processing department, our robots play a crucial role in enhancing efficiency, consistency, and quality.

Table of contents

Raw Material Management and Processing

Robotic Arms for Raw Material Dosing:

At our furnaces, we have robotic arms that assist our colleagues in filling molds. The robot places a collection tray under a raw material silo and weighs the plastic powder. Once weighed, the robot moves the tray above the mold and releases the material.

This method ensures that the raw material is accurately weighed and the mold is filled efficiently.

Rebagging Robot:

A robot specifically designed for rebagging 20kg raw material bags into a big bag. This robot not only increases productivity but also contributes to workplace safety by eliminating heavy lifting tasks.

Post-Processing and Assembly

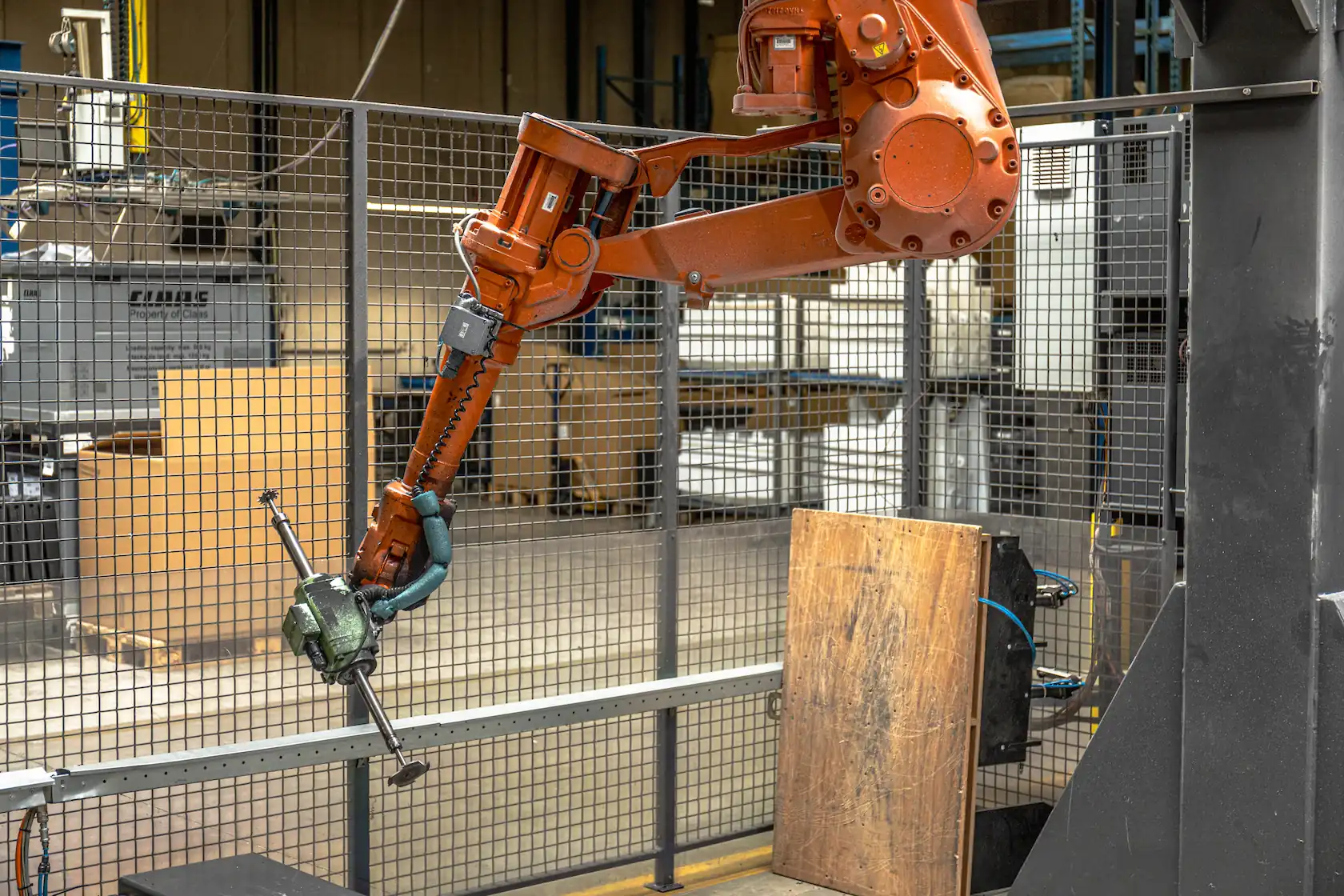

ABB Robots for Post-Processing:

Four ABB robots are integrated into our post-processing department, where they perform tasks such as drilling and milling with precision. These robots enhance the quality and consistency of our products.

Gluing Robot:

A specially designed robot is used for gluing products, utilizing advanced techniques to bond rubber to polyethylene. This robot ensures strong and durable connections, essential for the functionality and longevity of our final products.

Human-Robot Collaboration

Our goal is not to reduce the number of colleagues by deploying robots. Instead, we aim to create a collaboration between our colleagues and robots. By assigning robots to repetitive or physically demanding tasks, our colleagues can focus on more strategic and creative aspects of their work.

In the coming years, we will expand with colleagues specializing in engineering and robot engineering, ensuring continued growth in this area. Additionally, we maintain close contact with relevant vocational, higher professional, and university programs, offering students opportunities to intern and graduate with us on these technical subjects.

)