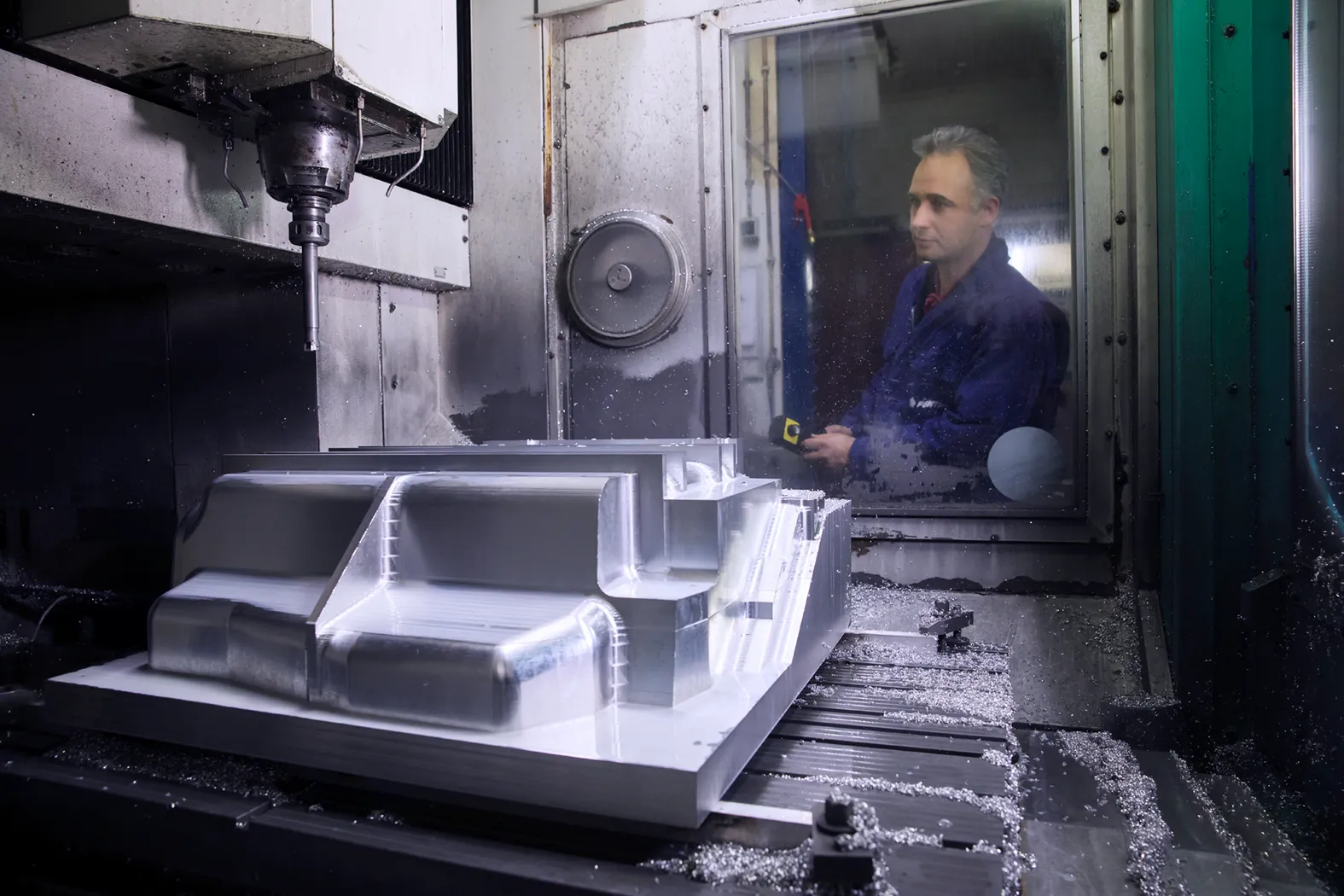

Rotational moulding

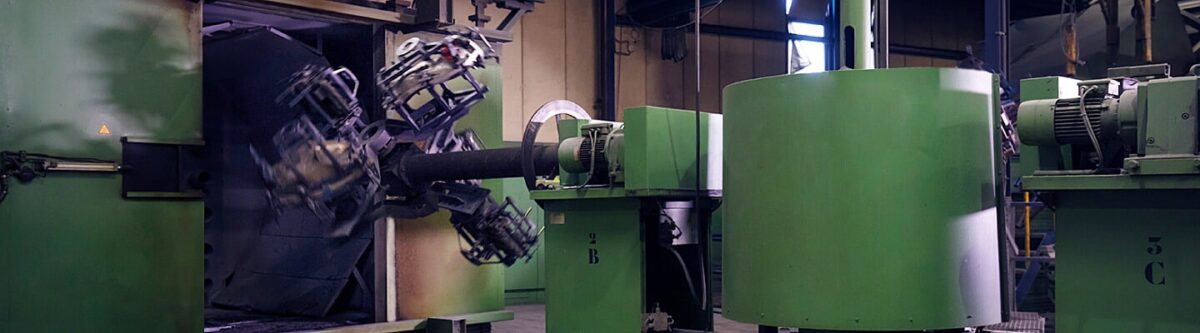

The art of mould makingRotational moulding is known as an advanced manufacturing process in which plastic powder is placed inside a mould. This mould is heated while rotating around two perpendicular axes. Due to this unique rotation, the plastic powder melts and evenly coats the inside of the mould. This results in a hollow product with a lot of design freedom regarding shapes and throughputs, something that is often difficult to achieve with other methods.