CLAAS

Lighter tank saves fuelThanks to our sophisticated wall thickness design, the new fuel tanks are 25% lighter with identical stability. This allows CLAAS to improve their fuel efficiency without compromising on safety.

We manufacture custom plastic products, exactly the way you envision it. And more lightweight, stronger and more sustainable if possible. Because we perfect the technique of mould construction and rotational moulding every day.

About Pentas

The possibilities of plastic rotational moulding are endless. From fuel tanks for agricultural machines and slosh dampers for windmills to toilet cabins… The more challenging the better. It takes a lot of technical knowledge and boldness to realise the right future-proof solutions. And we have everything it takes to do just that.

Rotomoulding

CLAAS

Lighter tank saves fuelThanks to our sophisticated wall thickness design, the new fuel tanks are 25% lighter with identical stability. This allows CLAAS to improve their fuel efficiency without compromising on safety.

Working method

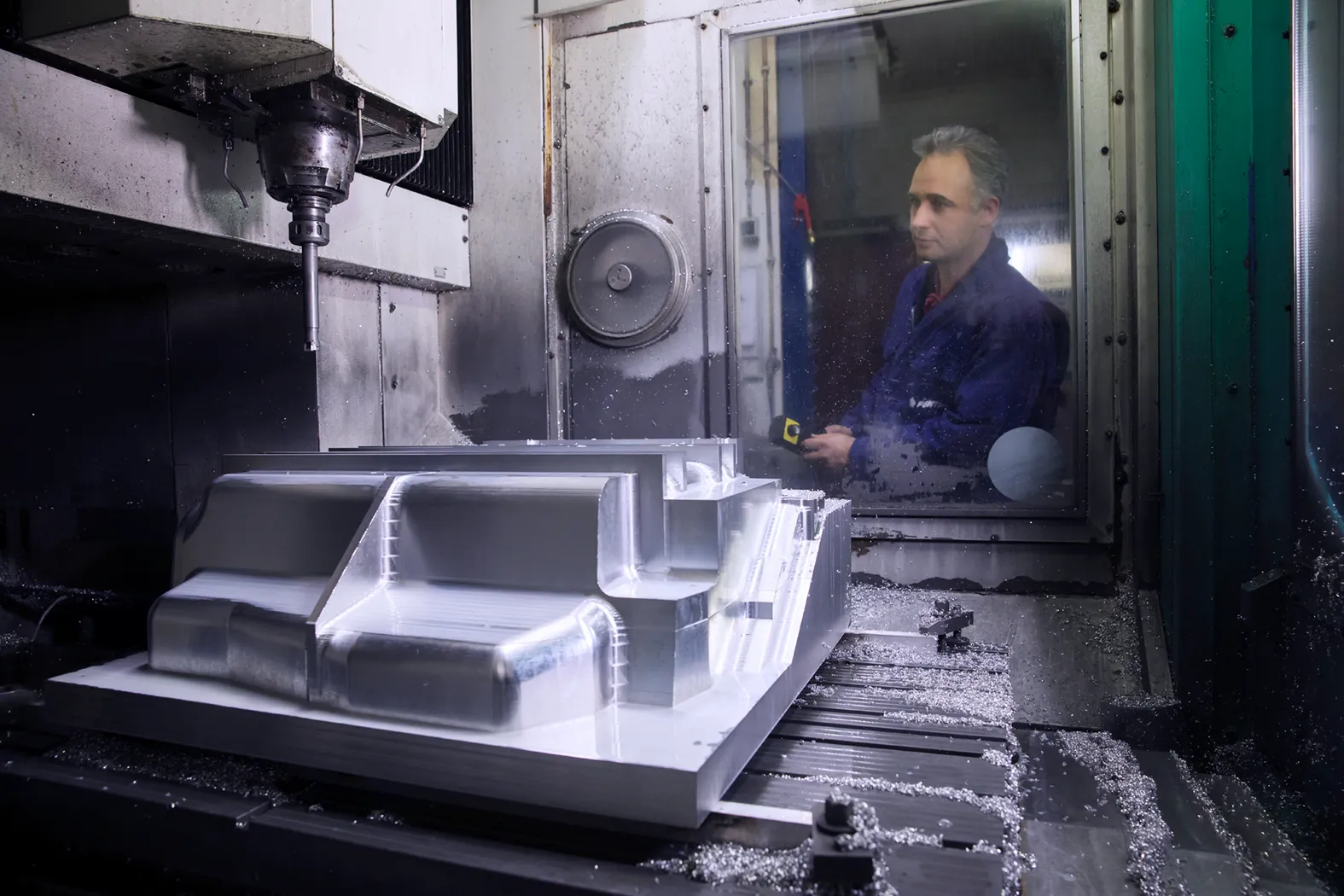

Clients appreciate in-house mould constructionIn a nutshell, agility and confidential information security are the benefits of in-house mould construction.

Rotational moulding

The art of mould makingRotational moulding is known as an advanced manufacturing process in which plastic powder is placed inside a mould. This mould is heated while rotating around two perpendicular axes. Due to this unique rotation, the plastic powder melts and evenly coats the inside of the mould. This results in a hollow product with a lot of design freedom regarding shapes and throughputs, something that is often difficult to achieve with other methods.

Historie

Our history at a glanceFor half a century, Pentas has been at the forefront of innovation, manufacturing the most complex products through rotational molding for a wide range of customers. Our extensive experience has created a treasure trove of history, ranging from producing surfboards to realizing an award-winning plastic tank for CLAAS. We are eager to share more about all our highlights in 50 years of Pentas.

Sustainability

The future of recycling in the rotational moulding industry: challenges, innovations, and sustainabilityThe plastics industry is facing significant changes, as the assumption of using virgin materials for manufacturing products is shifting. This change is driven by increasing environmental awareness and the need to reduce the consumption of new raw materials. There is an urgent demand for smart ways to reuse and recycle plastic waste, with reference to the Waste Framework Directive (WFD) within European regulations.